Guide to Rigid Signage Materials

When dealing with a signage company, you’re often confronted with a lot of different material choices for what your sign is made of, and it can be quite hard to work out what is actually right for your situation without knowing what each material is. This can sometimes be even trickier when browsing a web store for off-the-shelf signage.

It’s easy to think that ‘more expensive = better’ but that isn’t always true. Some materials are inherently more expensive than others and may not actually suit your specific situation. On the other end of the spectrum, it can be easy to simply opt for the cheapest option that you’ve been given, but that will come with its own set of limitations or issues. Then, there are situations where the only real difference is how something looks and whether it suits your aesthetic.

This guide will help you to make an informed decision about which materials are right for you and what you’re hoping to achieve with your signage. Note that this is a broad guide that outlines standard uses for some of the more commonly used signage materials but may not cover every possibility. There are limitations to what you can and cannot do with a material and for more complex requirements (such as high-end fabricated freestanding signs using unusual materials) these limitations must be taken into consideration on a job-by-job basis. In these scenarios, discussion between the industrial designer, engineer, and the manufacturer is essential as there is a vast difference between what works on paper in a design and what is physically possible to fabricate using the desired materials.

Material List:

ACM / ACP

Acrylic

Hardened PVC

Corflute

Foamcore / Foamed Board

Colorbond

Aluminium

Anodised Aluminium

Steel

Stainless Steel

Timber, Plywood & Veneered MDF

MDF

Aluminium Composite Material / Aluminium Composite Panel (ACM / ACP)

Common thicknesses: 3mm, 4mm (less common 2mm lightweight sometimes used)

3mm ACM is the most versatile and commonly used signage substrate. In more recent years it has received a fair amount of negative media attention due to its incorrect usage by builders that resulted in serious apartment fires. For signage however, it remains one of the best materials for versatility, quality, longevity, and price.

3mm ACM is the most versatile and commonly used signage substrate. In more recent years it has received a fair amount of negative media attention due to its incorrect usage by builders that resulted in serious apartment fires. For signage however, it remains one of the best materials for versatility, quality, longevity, and price.

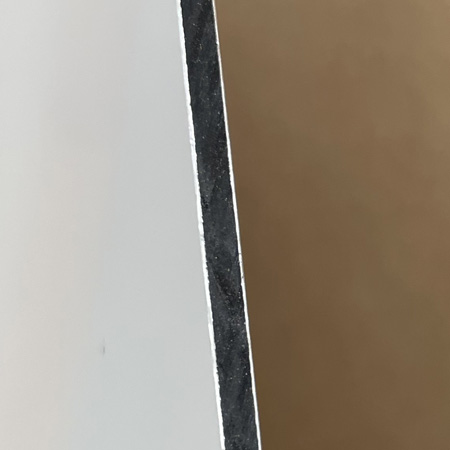

When cut, the black or grey internal core and the edge of the aluminium skins are visible along the edge of the sign. For most scenarios this isn’t visually distracting in any way, however if budget permits, straight edges can be bullnosed which involves folding the edge down on itself and cutting off the excess material so that the edges are the same colour as the face. Unless it’s a high-end job, bullnosing isn’t necessary and can be a waste of money as the edge of the material is rarely seen. If the panel has digital print or edge to edge vinyl applied to it, the vinyl can also be wrapped around to the rear, effectively hiding the material edge.

ACM can be purchased with either the standard PE core, or with a fire-rated core at a premium price which meets building code fire safety regulations. As restrictions are being tightened on the use of ACM in building projects, the fire-rated core is being specified on jobs and quotes more frequently, but it is important to remember that is not always legally required in signage and in many cases serves no actual purpose. For signage, the use of this fire-rated ACM is currently only necessary on building signage of a certain size, and in use in specific types of buildings where the quantity and coverage of flammable core can have an actual negative impact in a fire. On small signs like little wall mounted wayfinding panels or a once-off logo in an office reception, the fire rating on the core really does not contribute anything except unnecessary cost. While it may seem easy to be talked into spending the extra for the fire-rated core on these tiny signs for ‘peace of mind’, remember that the adhesives used to mount the panels to the wall are also highly flammable, and the coverage of the core pales in comparison to the other flammable items found in everyday office interiors that surround it.

ACM can be purchased with either the standard PE core, or with a fire-rated core at a premium price which meets building code fire safety regulations. As restrictions are being tightened on the use of ACM in building projects, the fire-rated core is being specified on jobs and quotes more frequently, but it is important to remember that is not always legally required in signage and in many cases serves no actual purpose. For signage, the use of this fire-rated ACM is currently only necessary on building signage of a certain size, and in use in specific types of buildings where the quantity and coverage of flammable core can have an actual negative impact in a fire. On small signs like little wall mounted wayfinding panels or a once-off logo in an office reception, the fire rating on the core really does not contribute anything except unnecessary cost. While it may seem easy to be talked into spending the extra for the fire-rated core on these tiny signs for ‘peace of mind’, remember that the adhesives used to mount the panels to the wall are also highly flammable, and the coverage of the core pales in comparison to the other flammable items found in everyday office interiors that surround it.

Visually, ACM is a low-cost alternative to painted aluminium, and in some situations is preferable to acrylic for its durability and rigidity. It is perfect for mid-to-long term signs (depending on the individual scenario and what the applied graphics are made from), and thanks to its high versatility in processing it, can be used in a variety of different ways on different types of signs.

We recommend it for use in:

Statutory signs

Safety signs

Freestanders and pylons

Fascia and front of store signage

Building and logo signs

General sign panels

Acrylic

Common thicknesses: 1.6mm, 2mm, 3mm, 4.5mm, 6mm, 10mm, 15mm, 20mm, 25mm (other thicknesses such as 5mm, 30mm and 40mm may be available from some suppliers)

Acrylic sits alongside ACM as one of the most used sign materials available. It comes in a huge number of thicknesses, colours and finishes, can be processed very easily in many different ways, and in most cases is usable both indoors and outdoors. It’s used in 3D letters, flat and heat-formed sign panels, and any sign that needs illumination, and can be laser or router cut, painted, and fabricated. It can also be used as an alternative to glass as it is more resistant to impact and won’t shatter as easily, though certain treatments can cause it to crack.

Acrylic sits alongside ACM as one of the most used sign materials available. It comes in a huge number of thicknesses, colours and finishes, can be processed very easily in many different ways, and in most cases is usable both indoors and outdoors. It’s used in 3D letters, flat and heat-formed sign panels, and any sign that needs illumination, and can be laser or router cut, painted, and fabricated. It can also be used as an alternative to glass as it is more resistant to impact and won’t shatter as easily, though certain treatments can cause it to crack.

Unlike ACM, the edge of acrylic is the same colour as the rest of the solid material (except on multilayered sheet) and when flame polishing or laser cutting, has a perfect shiny finish. This perfect edge means that acrylic is preferable for things like individually-cut 3D lettering where the edges are highly visible to the viewer.

Acrylic can be 2-pack painted to suit any colour palette, however it is also available in many different styles and colours if a highly specific PMS or corporate colour isn’t necessary. Most coloured acrylics are only available in the 3mm and thinner sheets, but using a pre-coloured sheet can be in some ways beneficial over painting, as the colours are long lasting and penetrate the full way through the sheet rather than just being a coating on top.

Acrylic can be 2-pack painted to suit any colour palette, however it is also available in many different styles and colours if a highly specific PMS or corporate colour isn’t necessary. Most coloured acrylics are only available in the 3mm and thinner sheets, but using a pre-coloured sheet can be in some ways beneficial over painting, as the colours are long lasting and penetrate the full way through the sheet rather than just being a coating on top.

Many people will refer to it as ‘Plexiglas’, however this is actually a brand name and not the type of material. Plexiglas is a premium acrylic brand which retails at about 2-3 times the cost of most industry standard acrylic. If the premium product is required (or has been proposed by your sign company) for your project, it’s important to ensure that your supplier is giving you actual Plexiglas-brand acrylic and not substituting it for the cheaper alternatives while charging full price simply because they think you don’t know the difference.

We recommend it for use in:

Individually cut letters

Illuminated letters, signs, and lightboxes

Most internal signage

Braille signs

Poster pockets, desk signs, and other applications where folding is needed

Hardened PVC

Common thicknesses: 10mm, 15mm, 20mm, 25mm

Hardened PVC sheet is an incredibly light product that can be great for applications where weight is an issue, but a thick sign panel is required. It features a super-smooth, hard white outer layer with a dense yet porous inner white core, and can be used indoors and (if using the correct product), outdoors as well. It is important to note that not all brands of hardened PVC are UV stable, and exposure to sunlight and heat can damage them.

Hardened PVC is best used on router-cut individual letters and logos, especially ones that are left white, as the natural panel finish is brilliant white and the sheet cuts beautifully. It isn’t really recommended to use full sheets (or even large panels of this), especially in areas where full exposure to excessive sun and heat directly hits the panel, as this excess heat can cause even UV stable panels to warp.

The cost of this sheet relative to its thickness and weight makes it perfect for use in fabricated illuminated letter backings (where the illumination is not required as it is most definitely an opaque product), and there are a wide number of uses for the product that generally go unseen inside more complex signs.

Hardened PVC can also be 2-pack painted, however the exposed edges of the panel are porous and will need to be filled and sanded back to a smooth finish before painting or they simply will not have the same level of finish as the faces. This adds extra labour and cost to the job, as it makes the painting more labour intensive than something like aluminium or acrylic. However if done correctly, painted hardened PVC looks incredible.

We recommend it for use in:

Individually cut letters

Internally in signs (such as fabricated letter backings)

Lightweight internal signs, like wayfinding

Corflute

Common thicknesses: 3mm, 5mm (although a variety of other thicknesses up to about 10mm are available at corflute suppliers as they’re used by other industries)

Corflute is the go-to product for short-term signage, thanks to its extreme lightness of weight, low price, and weather resistance. Formed from fluted twin-walled polypropylene, corflute is semi-rigid (though it can be damaged by folding it along the fluting) and is suitable for both indoor and outdoor use. Though the fluted design of the panel means that it’s hollow and therefore weighs next to nothing, it causes the faces of the panel to be visibly ‘ribbed’.

The faces and flutes of corflute are thin enough that the panels can be knife cut (particularly easy to do when following the line of the fluting), and it can also be form cut on a router for use on things like installation templates. The light weight nature of corflute combined with its (relative) rigidity, and ease of folding makes it perfect for things like temporary point-of-sale displays, but it can also be used for flat panel signs for short-term advertising on hoarding or fencing. In these situations, it’s best to apply holes for zip ties or wire using eyelets, rather than simply drilling a hole, which could be torn down by vandals.

Corflute can be directly printed on, or it can have cut vinyl graphics or digitally printed vinyl attached to the face. Regardless of the methodology and thickness of the attached vinyl/print, the ribbing on the face will still be visible. Digitally printed vinyl does have the added benefit of being able to be wrapped around to the rear of the panel, effectively hiding the ‘ugly’ edges of the sheet where the inner plastic fluting can be seen.

In signage, corflute is generally supplied as white sheet, however craft and trade good stores will also sell it in the basic primary colours plus black, however in general the signage-grade corflute tends to be sturdier and less prone to bending / folding than craft-grade corflute which features thinner skins and fluting. Since the product is so cheap and is intended for short-term promotional use, it’s not something you would bother 2-pack painting due to the cost of the process, so print or vinyl graphics are more appropriate if a specific colour of sheet is needed.

We recommend it for use in:

Short-term signage

Event / promotional signs

Temporary point-of-sale displays

Foamcore / Foamed Board

Common thicknesses: 3mm, 5mm, 10mm, 20mm

Foamcore or Foamed Board is more commonly used by artists for its smooth printing face and ease of cutting, however it does still serve a purpose in the sign industry. Formed of a light-density polystyrene foam core with 2 hard printable faces (usually of a thick, glossy paper or card, wood fibre panel, or veneer), it is used for extremely light-weight short-to-mid-term indoor signage.

Foamcore is more expensive than corflute, but it benefits from having a superior face and edge finish. The face is perfect for direct printing, and will also provide good surface adherence for vinyl graphics. Its light density and (often) paper/card faces means that it can be hand cut with a knife making processing it very accessible for most people. The lack of outdoor durability makes it a less versatile product than other short-term signage substrates, but it is still an effective product in specific scenarios.

Some suppliers carry an alternate product which bridges the gap between foamed board and hardened PVC board. This light-weight, mid-range PVC sheet is cheaper than hardened PVC and is closer in density to foamcore but with the added benefit of some outdoor use where constant direct sun and extreme weather conditions cannot affect the panel. It is also available in thinner sheets than hardened PVC (such as 3mm and 6mm), making it useful for a wider range of temporary signs. On the downside as this alternate product isn’t traditionally UV stable, the uses for it can be quite situational and most people will simply opt for corflute thanks to its durability and lower price point.

We recommend it for use in:

Short-to-mid-term indoor signage where corflute is not high enough quality

Colorbond

Common thicknesses: 0.55mm

Before the advent of ACM, Colorbond was the go-to signage substrate for almost every fascia sign or general signage panel. Now, its popularity has fallen to the point that many sign supplies companies don’t even carry it, and it must be sourced from steel suppliers and building supply companies instead. Despite this, Colorbond is still a fantastic, durable product and it serves many uses in signage.

Formed of a rigid 0.55mm coated steel sheet, Colorbond is great for both indoor and outdoor use. The biggest disadvantage of Colorbond is that it is quite heavy despite how thin the sheet is, making the significantly lighter ACM a more popular option in a wider range of scenarios. Being such thin steel sheet, Colorbond is also less versatile in terms of how it can be processed, and ways in which it can be used however it can be folded using a sheet metal folder resulting in a beautifully crisp fold line.

One of the biggest benefits of Colorbond over ACM is that being steel rather than aluminium, it is magnetic. This opens up options for the creation of interchangeable signage using magnetic strips, and other types of sign boards where having magnetic components is desired, such as community notice boards and sales tallies. It also has a longer life expectancy than ACM provided that the paint coating is not damaged resulting in the exposure of the steel to the elements. In most scenarios however, both ACM and Colorbond substrates will outlast any vinyl graphics that are applied to them.

We recommend it for use in:

A-frame panels

Situations where ACM may not be suitable or where great durability is desired

Aluminium

Common thicknesses: 2mm, 3mm

3mm is the most commonly used thickness of raw aluminium in signage panels, but it is available in many other thicknesses in both sheet (between 0.5mm and 6mm), and plate (upwards of 6mm thick)

Whenever you see a pylon sign or freestander, beautifully painted sign panels with perfect folded / welded returns, council and school signs, or any other hard-wearing impressive signage, the sign faces (and in many cases the underlying framework) is likely to be made from aluminium. Aluminium sheets are lighter than steel, can be precisely fabricated, are suitable for both indoor and outdoor use, and don’t need to be hot or cold galvanised to be resistant to corrosion, making aluminium ideal for almost any situation provided you have the budget for it. It can be 2-pack painted to a pristine finish, and is arguably the longest lasting of all of the common sign substrates.

Unlike ACM, raw aluminium sheets are aluminium all the way through giving them significantly more weight, but also a far more rigid finish. Where 3mm ACM may pucker, ripple, or buckle, an aluminium equivalent would hold its shape far better under most circumstances. This is why you’re likely to see aluminium used in situations where ACM simply wouldn’t hold up or be suitable (such as fabricated channel letters and large pylon signs).

Aluminium sheets most commonly come in both a raw or an anodised finish, though we will discuss uses for the anodised aluminium section below. This means that it needs to be painted or have vinyl applied to the face as the raw finish is not attractive on its own. Like acrylic, it can be 2-pack painted in any colour or finish that you desire, which is ideal for corporate signage packages where both durability and consistency are necessary. Aluminium is also often used in individually cut letters, though they do come at a higher price point than the acrylic equivalent.

Pre-finished aluminium sheets are starting to become more common now as concerns arise around the suitability of ACM as building cladding. As these sheets increase in popularity and become cheaper to purchase, their use in signage applications will also increase, making these a viable competitor to ACM.

We recommend it for use in:

Long term signage applications

Pylons and freestanding signs

Fabricated channel letters

Mid-to-high end signage systems

Anodised Aluminium

Common thicknesses: Pre-treated sheet - 1.5mm, 2mm, 3mm

Otherwise, any raw aluminium parts that will fit into the anodiser’s acid bath

Anodised aluminium is a special treated form of aluminium which has a beautiful and hard-wearing protective finish that allows for the natural metal look of the aluminium itself to be a feature. Unlike raw aluminium which has an unfinished look to it without paint, anodised aluminium is clean and can have a range of colours imparted into it during the anodising process. Colour anodising is unlike painting which hides the metal surface; it dyes the surface treatment allowing the natural grain of the metal to be visible.

Anodised aluminium can either be purchased in pre-treated sheets, or aluminium parts can be individually treated, allowing for fabricated signage to be fully anodised. The process involves the aluminium being clamped, then dipped into an acid bath and fully immersed. An electrical current is then passed through the part, creating an anodic film across the surface of the material. The thicker this coating, the longer the lifespan of the aluminium. While getting parts individually anodised is more costly than using pre-treated sheets, it means that the cut edge of the aluminium will maintain the anodised look, and parts that need to be welded or formed can have a consistent finish (provided the correct grades of aluminium are used and welds are properly finished). When cutting a pre-treated sheet, the cut edge of the material will be raw aluminium and thus will not have the same look or protection.

Due to its high-end finish and durability, anodised aluminium is often found in expensive apartment buildings and hotels, shopping centres, office blocks and other facilities where signage needs to last a long time while maintaining its quality. In order to get the best lifespan out of the aluminium, care has to be taken when cleaning as certain chemicals can cause discoloration of the surface, and if the cleaning cloth is covered in dirt or grime it can also leave fine scratch marks.

We recommend it for use in:

Statutory and braille signs

Wayfinding

Small internal signage (ie. Door identification)

Steel

Common thicknesses: 2mm, 3mm (where used in relation to signage faces); other thicknesses are also available but are more commonly found in extrusions used for structural purposes

Steel is less commonly used than stainless steel or aluminium for signage faces as it tends to be more expensive and labour intensive to achieve results that are quite simple with aluminium. The best uses for steel tend to be structural ones as it is a far heavier and more structurally sound material than aluminium, and so steel extrusion can be largely found in large format sign frames such as pylons.

Unlike aluminium which has a fairly high corrosion resistance, steel will quickly rust if exposed to the elements unless galvanised or otherwise treated. Similarly, if steel comes into contact with a dissimilar metal like aluminium (for example if a pylon has steel framework with aluminium panels mounted to it), it will also begin to corrode unless suitable gaskets (such as rubber or nylon) are used to separate all points of contact. The benefit that you do get with steel over aluminium however, is that steel is harder and heavier and this means that where an aluminium sheet may pucker or buckle, a steel one likely will not.

In some situations, rust can actually be aesthetically desirable, especially in certain rustic styles of signs or art. As rust ruins the integrity of the material and if bad enough can actually penetrate fully through sheet, a specific type of steel must be used in order to safely achieve the look. This product is called Corten and is specially treated so that rust remains on the surface of the steel and will not affect its structural integrity. You’ll often see this type of sign used externally, especially in large signs that allow the beauty of the rust to shine. The unfortunate side effect of using rusted Corten is that rain will cause the rust to run down whatever is beneath the steel, and this can be both difficult to clean and quite unsightly.

In addition to rust, steel can also be painted or a range of chemical treatments can be applied to get a lasting oxidised finish on purpose. Oxidation can achieve many different colours and this technique allows for the steel sheet’s underlying finish to show.

We recommend it for use in:

Signage where aluminium is not sufficient structurally

Large external signs where a rusted aesthetic is desirable

Stainless Steel

Common thicknesses: 1.2mm, 1.5mm, 2mm, 3mm (other thicknesses available for specific purposes)

Stainless steel is the refined cousin to raw steel sheet, and is very commonly used in braille signage, statutory signage, and wayfinding signs (amongst others). Similar to anodised aluminium, its face has a high-end aesthetically pleasing look which does not need paint or other forms of coating to be complete and usable. Stainless steel is hard, durable, and available in a variety of finishes although the most popular and widely used is the no. 4 linished style. It is also available in pre-coloured sheet through specialty suppliers such as Rimex and is similar to coloured anodised aluminium in that the finish of the sheet metal is visible as part of the colour.

Stainless steel is far more resistant to corrosion than raw steel, but it still can rust over time and with exposure to certain elements (especially things like chlorine and salt). Many different grades of stainless steel are available for different purposes, with 304 and 316 most commonly seen in signage. Their use is largely dependent on the specific situation as each grade has different qualities. 304 stainless is the cheaper grade and for most scenarios it is more than sufficient. It is also visually indistinguishable from the more expensive 316 stainless. This higher grade of stainless steel has 2% molybdenum which provides better resistance to corrosion, salts and chlorine amongst others. Because of its additional cost it is normally only used for signage which is located in or close to marine areas, or signs that are exposed to additional chemicals such as at pools.

One thing to remember about these grades of stainless is that they’re technically non-magnetic. Certain treatments such as bending or drilling can cause partial magnetism at the areas of stress, but for the most part magnets will not stick to the sheet. If you need a reliably magnetic surface, it’s best to use Colorbond, or painted steel.

We recommend it for use in:

Braille signs

Wayfinding signs

Statutory signs

Feature elements on freestanders and pylons

Timber, Plywood & Veneered MDF

Common thicknesses: 3mm, 5mm, 10mm, 15mm, 19mm (the list keeps going, and timber can be planed to specific thicknesses as well)

Timber signs are not something that you see all that often, especially in comparison to things like ACM and acrylic. As a natural material, they do tend to involve more work than pre-finished sheets and regular upkeep is required in quite a lot of scenarios in order to keep them in good condition. However, timber signs can have a beautiful aesthetic and can be used very effectively if done well.

Timber for signage comes in a variety of sheet formats, and sometimes planks designed for construction use can be used to great effect too. Sheets can be found in solid timber (though these tend to be quite expensive and somewhat difficult to source), plywood, and veneered panels that feature timber veneer faces with a MDF core. Timber planks and posts can be used in their original format, or can be laminated together to form sheets in thicknesses that are normally not available.

Bamboo sheets and plywood are also quite popular, and their use in signage is increasing slowly. Much of the bamboo available in the Australian market is sustainably farmed, making it ideal for people seeking a more environmentally friendly alternative to the industry standard substrates. Bamboo is available in both raw and finished solid sheets, bamboo plywood, and also veneered MDF panels. The biggest issue with raw and untreated bamboo is that it will swell when in contact with water (which indeed most timber sheets will) and thus is not recommended for external use.

We recommend it for use in:

Braille signage

Internal signs

Posts for external signs in natural environments (if treated properly)

Signage where a natural aesthetic is desired